In our last post, we discussed how a mobile version of Physical Inventory Count for Oracle Cloud can make the physical counting process easier in Oracle Cloud SCM. However, there are other ways to count inventory. The most common method is a Cycle Count or Stock Take, and most businesses use this to replace an annual physical count or to count specific items more frequently. Let's take a look at what Cycle Counting looks like in Oracle Cloud.

The difference between the two types of counts is that Physical Inventory is a full stock count usually carried out once or twice a year, whereas Cycle Counting is done perpetually. As with Physical Inventory, this can either be performed using a directed/scheduled or manual approach.

When completing Cycle Counts in Oracle Cloud, there is some initial setup that needs to be performed. How you set up Oracle will depend on what approach to Cycle Counting your business prefers.

This method can be used if you wish to periodically schedule counting of items.

You can use an Oracle-recommended strategy called ABC Analysis to analyse your inventory and break up your items into classes based on criteria you specify. For example, on-hand value, on-hand quantity, historical transaction quantity and historical transaction value.

You can setup cycle counts to be performed based on your ABC Analysis. In there, you can determine the frequency of your cycle counts and how many times a year each class of items should be counted.

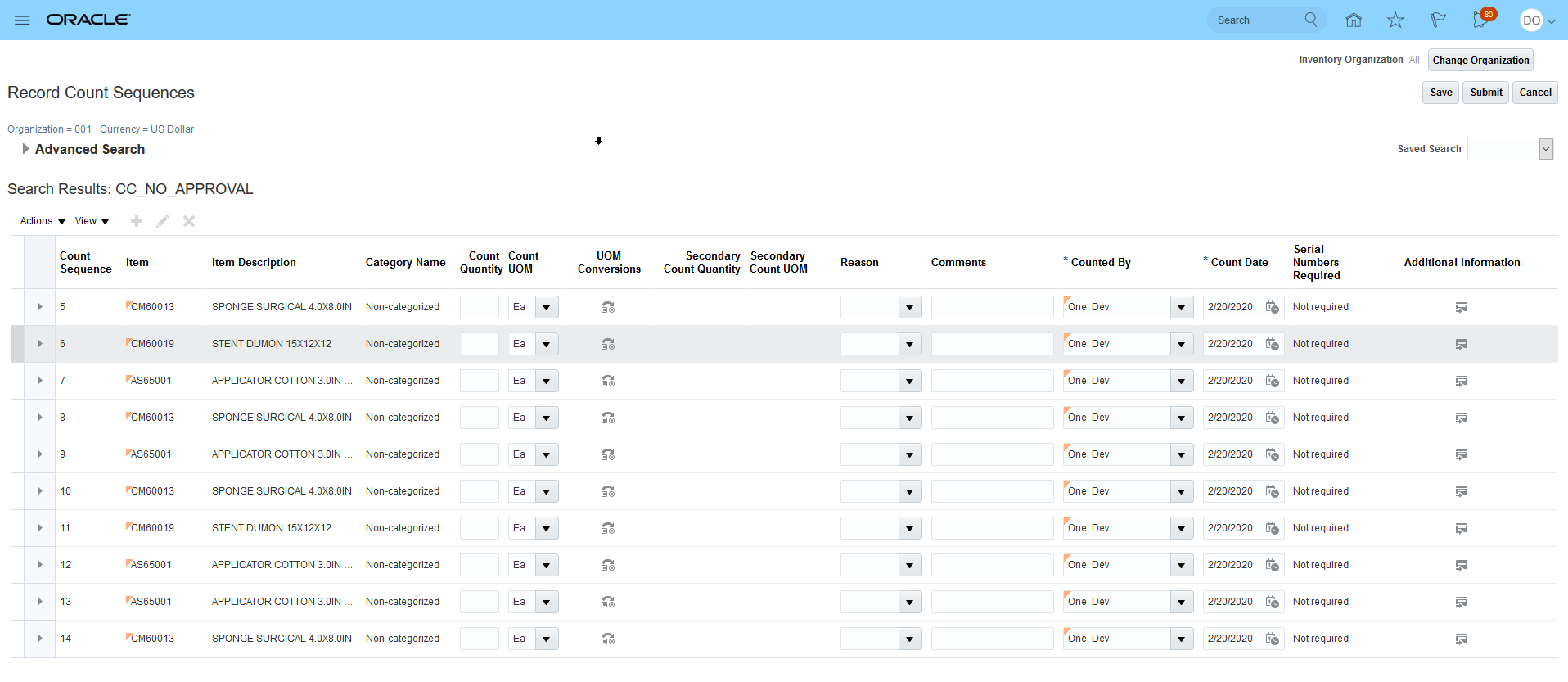

Oracle will then generate count sequences based on this information provide.

Figure 1: Example of Cycle Count Sequence (Record Cycle Count Sequence screen)

This method can be used for “one-off” item counts outside of the usual schedule.

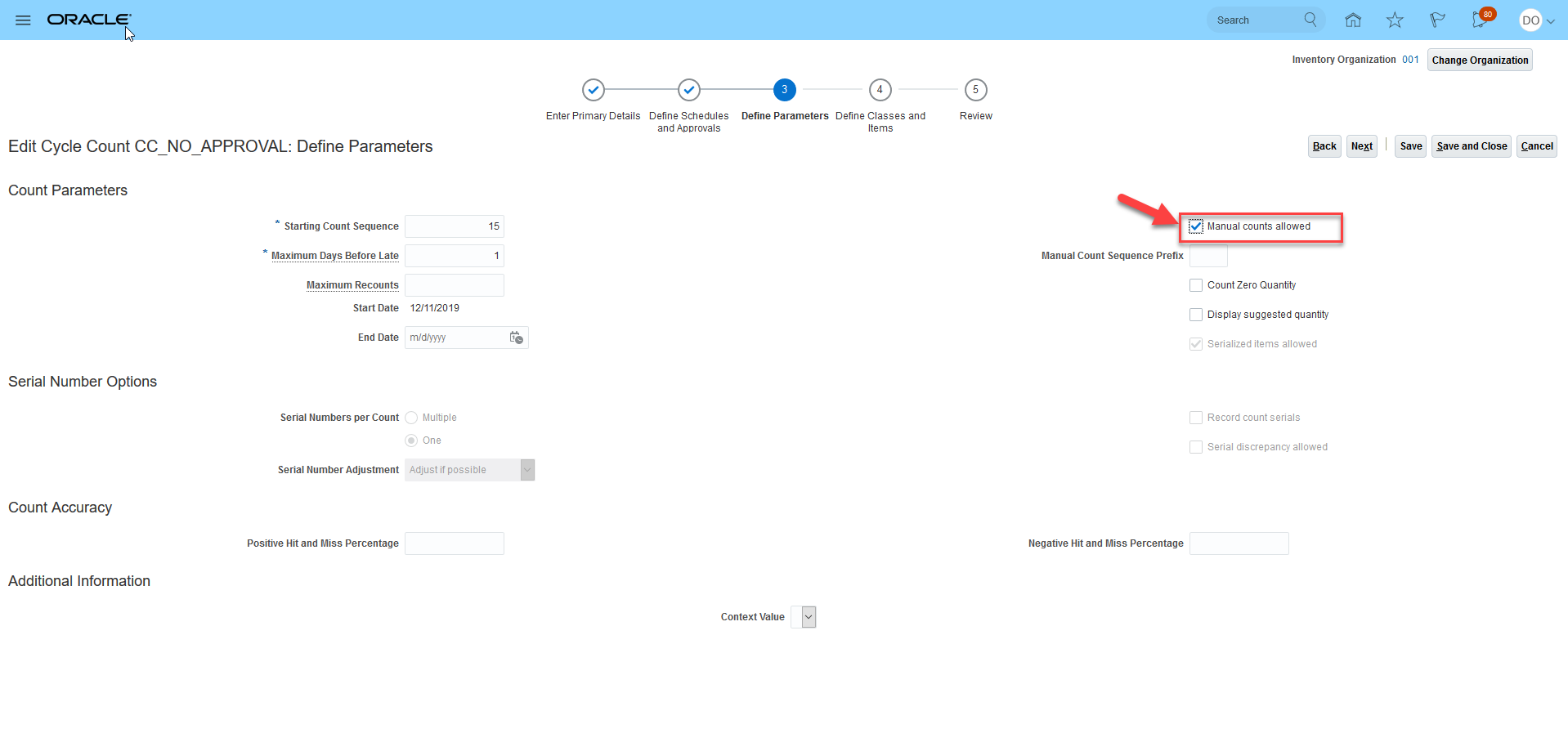

You can use existing scheduled Cycle Counts or create standalone Cycle Counts, however to enable the manual count function, you must have the flag checked “Manual Counts Allowed.”

Figure 2: Manual counts allowed (check box)

Completing a Cycle Count in Oracle without a mobile solution involves a few manual processes. This includes printing out the list of items that need to be counted, sending users to find the items and then counting and recording data in Oracle. This process can be error-prone due to the double-handling of data (writing on paper and then data entry into Oracle).

RF-SMART identified the opportunity to take a manual process and streamline to make it a mobile, cloud-based inventory process that is quick and easy to use and can reduce total execution time. The RF-SMART Cycle Count function directs workers through the count process and reduces the chance of data errors by scanning.

Unlike Physical Inventory Counts, with Cycle Counting you can count and perform your day-to-day activities at the same time. There is no need to stop transacting in Oracle until the count is complete because Oracle will factor in these transactions into the adjustments, and all of the data is updated in Oracle in real-time.

Once the Cycle Count has been defined in Oracle, you can use the RF-SMART Cycle Counting functionality to perform the count itself.

There are two versions of RF-SMART’s Cycle Count: Cycle Count Manual and Cycle Count Directed 02.

Figure 3: Example of Cycle Count in RF-SMART

Now that you understand how Cycle Counting in Oracle and RF-SMART works, here are some tips for changing how the mobile function works to meet your individual business processes.

Preparing for a Cycle Count

Cycle Count Directed 02 Workflow Options

RF-SMART has added additional sorting options to route workers on the most efficient path through the warehouse:Cycle Count Manual Workflow Option

In Cycle Count Manual, we provide one workflow option:

The Nerds' Eye View blog is written by members of our RF-SMART Oracle Cloud development team. This series features behind the scenes insights into why we've developed different functionality and how you can best leverage it.

Read Part 1 on Physical Inventory Counts

About Scott Sellers: Developer of the Physical Inventory function. Working at RF-SMART for 3 years, joined the Oracle Cloud technical team in June 2019.

About Rachel Warren: Architect/Designer of the Physical Inventory function. Working at RF-SMART for 2 years. Previously worked with Oracle EBS, then switched to work with Oracle Cloud in 2017

Want to See More?

Get a monthly recap of our latest Educational Content.

© 2026 RF-SMART. All rights reserved. Privacy Policy