Barcode labels have been the industry standard in retail and logistics for over 30 years, and once implemented, is the most effective way to manage inventory. Commonly known as 1-D, 1-dimensional barcodes can hold more than one piece of information about the product it is attached to when scanned. When the scanner "reads" the barcode, it converts the lines and numbers using a translation language called barcode parsing to display the information held against that barcode (ie. product id, lot, expiry date).

In addition to point-of-sale applications, 1-D barcodes are also used for labeling raw materials and inventory management, providing a way to monitor inventory levels with less need for hands-on human intervention (and less room for human error).

They’re also used by the postal service and throughout the shipping industry as a whole, providing a more accurate way to track packages and ensure accurate picking and order fulfilment to final delivery.

1-D barcodes are widely utilized due to a few distinct advantages:

Unlike the standard 1-D barcode, 2-D barcodes, or QR codes, can store information in two directions (horizontally and vertically), while 1D barcodes can only store information in one direction (horizontally). This allows them to hold much more information. A 1-D barcode can typically store about 20 to 25 characters unless leveraging the GS1 global standard coding method.

The QR code bridges the gap between the digital and physical worlds. Not only can it store more than 4,000 characters, the QR code is also easily accessible. Since 2006, nearly 100% of smartphones are capable of scanning QR codes, providing opportunities for companies to connect and share information with consumers.

2-D barcode advantages include:

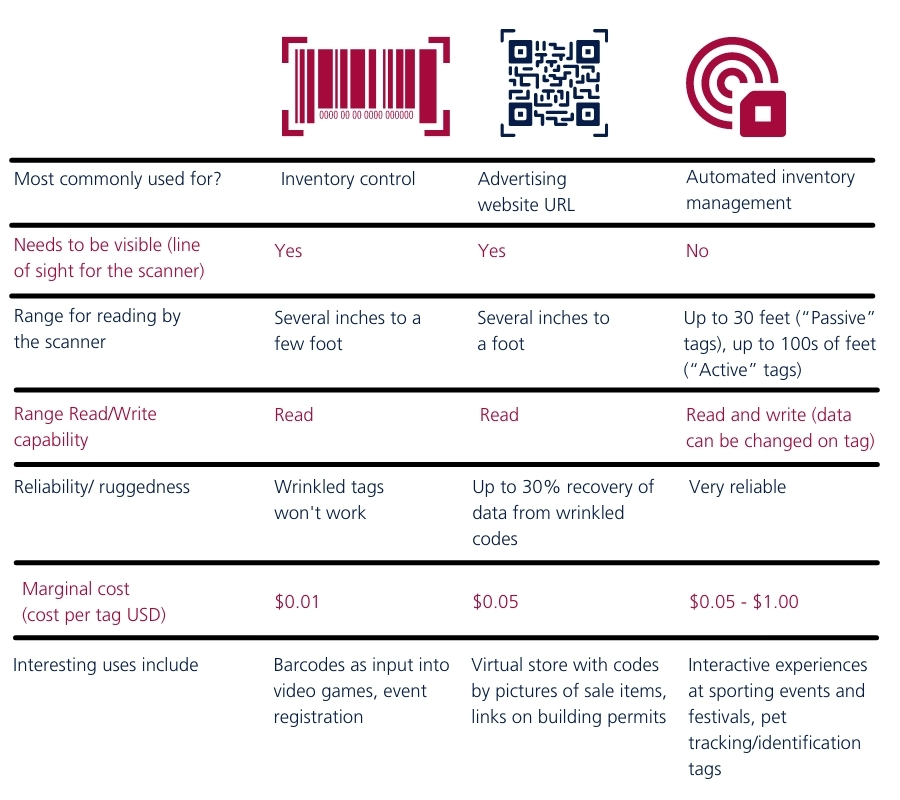

However, with both 1-D and 2-D barcodes, there needs to be a line of sight between the product barcode and the reading device and adequate light.

*Sourced from: HP Technology at Work

*Sourced from: HP Technology at Work

No matter what use you have for scanning technology, the companies that take advantage of any of its forms have a clear advantage over those that don’t.

Want to find out more about using barcode scanning?

Contact our team to find out if barcode scanning can help your warehouse operations.

Get a monthly recap of our latest Educational Content.

© 2026 RF-SMART. All rights reserved. Privacy Policy