The distribution industry is turning to new strategies and technologies that can increase efficiency and worker productivity. Customers are demanding faster turnarounds and correct orders – in most cases you get one shot to earn their dollars. Warehouse managers have to stay up-to-date on the latest trends and technologies that are shaping the industry. What does this mean for NetSuite customers and how do you know if your operations are ‘best in class’ or have room for improvement?

![Metrics-1]()

Determining Which Metrics to Measure

There are many metrics than can be used to measure DC performance. One industry-leading source is the DC Measures annual benchmarking study conducted by the Warehousing Education and Research Council (WERC). This study is done every year and examines the 30 key operational warehousing and distribution metrics.

![Top 5_WERC]()

In 2018, five of the top 12 metrics focused on employees, a sign of the tight labor market and wanting to squeeze as much efficiency into your workforce. There was shift in 2019, with operations prioritizing quality and capacity instead, a sign of e-commerce growth and the challenge DCs face around order fulfillment.

So, what are the key warehouse metrics you should be measuring in your distribution operations?

Top Warehouse Metrics for Measuring Success

1. Order Accuracy (percent by order)

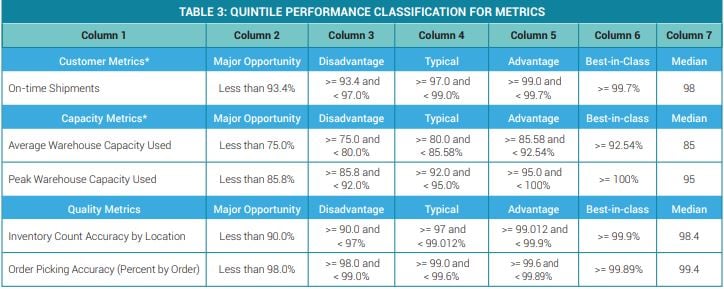

It’s no surprise that Order Picking Accuracy is number one. The 2016 WERC study found that Customer Service was the most prominent strategy DCs focused on and has remained at the top for the past 3 years. Customers expect to receive the correct order as quickly as possible. Incorrect picks result in higher labor costs, inaccurate inventory, delayed shipments if caught beforehand, and unhappy customers if not caught at all.

- What Does Good Look Like?

Order Picking Capacity Best in Class = 99.89%+

If your Order Picking Accuracy is less than 98%, this is an opportunity for improvement in 2020. Most companies fall between 99.0% & 99.6%, with an average of 99.4%.

- How Do You Improve Order Picking Accuracy?

If you want to improve order picking accuracy, reducing manual, paper-based processes is key to picking the right product correctly the first time. A mobile warehouse management system (WMS) can help. A mobile WMS controls the movement of your inventory, storing the location directly in NetSuite. Implementing a WMS can help you keep better track of your inventory and directly impact accuracy metrics.

2. Warehouse Capacity

Two KPIs you should measure involve how efficiently you are using your warehouse space. Average Warehouse Capacity Used is the average amount of warehouse spaced used over a specific interval of time, such as monthly or yearly. Peak Warehouse Capacity Used is the amount of space used during your designated peak seasons.

- What Does Good Look Like?

Average Capacity Best in Class = 92.54%

Peak Capacity Used Best in Class = 100%

If your Average Capacity is under 75% (average is 80-85%) or your Peak Capacity is less than 85.8% (average is 92-95%), your business has an opportunity to optimize your space.

- How Do You Improve Warehouse Capacity Metrics?

Are you maximizing every inch of your warehouse? Your inventory characteristics like number of items, the physical size of the items, how much you carry, the characteristics of inbound and outbound orders and storage configurations determine your capacity.

Visibility to real-time, accurate information is the key to successfully managing your inventory. If you don’t know where your items are and how fast or slow they turn over, it's difficult to properly stock your warehouse. During implementation of NetSuite, you will define not only your inventory, but also your location and item cube information. You can then run reports for information on your utilization. If you are also using mobile technology to eliminate error-prone manual data entry and execute on cycle counts, you can establish accurate inventory to prevent stock-outs while reducing safety stock by 1/3.

3. Inventory Count Accuracy by Location

We like to talk about having a complete picture of your inventory. But the reality is your inventory is always moving. Having the ability to know where items are located, how they are distributed across multiple locations and the ability to properly fulfill items is a critical part of day-to-day management. Without a smooth process, you end up with stock outs, delayed shipments, and unhappy customers.

- What Does Good Look Like?

Inventory Count Accuracy by Location = 99.9%

There really isn’t any room for error in this category with best in class operations having a 99.9% inventory count by location. If you are operating at less than 98%, your business has an opportunity for improvement.

- How Do You Improve Inventory Count Accuracy by Location?

This is another metric where using manual processes isn’t going to get you to the ideal numbers. If you are using pen and paper, there is an increased risk of errors. Using barcodes and scanning to automate this process can reduce errors and improve the productivity of your workers.

Currently, there isn’t a method in NetSuite to view multiple locations and their inventory. Using a location leveling solution can help you make real-time inventory management decisions with the ability to automatically transfer items between locations - resolving stockouts and low inventory levels without purchasing more inventory.

![Metric Classification Table_Werc]()

Key Takeaways from the WERC Study

One thing that is clear looking at these metrics is technology is only going to become more important to distribution centers as they look to meet high benchmarks. According to Logistics Management, in 2018 the use of a WMS reached 93%, the first time it topped the 90% mark. But at the same time, nearly half of all warehouses are still relying on paper-based (spreadsheets or paper) picking methods to fulfill orders.

In the WERC survey, to be considered “best-in-class,” performance levels must fall within the top 20% of all respondents. “Performance management truly thrives on consistency— In most cases for best-in-class operations, the only way to achieve higher performance is to commit to significant investment and risk.”

Implementing a cloud-based ERP like NetSuite with a Built-for-NetSuite mobile WMS like RF-SMART is one way to to modernize your supply chain. For more than 20 years, Oracle NetSuite has helped organizations grow, scale and adapt to change. RF-SMART helps NetSuite users manage inventory, assign work and measure performance and productivity. Real-time transactions update NetSuite ERP for an accurate picture of your operations.

Here are a few examples of how our customers are using NetSuite and RF-SMART to be best-in-class.

Joint RF-SMART and NetSuite Customers

Allied Hygiene

Allied Hygiene was able to increase their inventory accuracy from 75% to 99.6%.

Allied Hygiene found it impossible to maintain an accurate count of their inventory due to their manual paper-based method. Once implementing NetSuite and RF-SMART, they now experience less errors. Coupled with real-time data, this means a rapid improvement in accuracy and efficiency for their operations. “Now, if a customer rings and asks for an estimate on when they’re getting their order, sales admins can look at their screen and see if it’s picked and packed already.”

Skin Script

Skin Script was able to double their order picking, picking 500+ per day and offer same-day shipping with confidence their customers are getting the correct order.

Skin Script uses NetSuite + RF-SMART to complete sales order picking and packing. While Skin Script did not have bins prior to RF-SMART, as they moved to a new warehouse, they set it up to mirror the flow of transactions in RF-SMART. The result was a more logical warehouse. “I no longer have employees asking where items are, RF-SMART prompts them to the right location.”

Prior to RF-SMART, Skin Script employees were packing boxes immediately after they were manually picked, but the shipping label was not applied until later in the process, which resulted in errors. With RF-SMART controlling the picking and packing, orders are picked, packed and labeled in succession, with RF-SMART prompting users to scan at every step to ensure accuracy.