Why is Pick, Pack, Ship

Software Important?

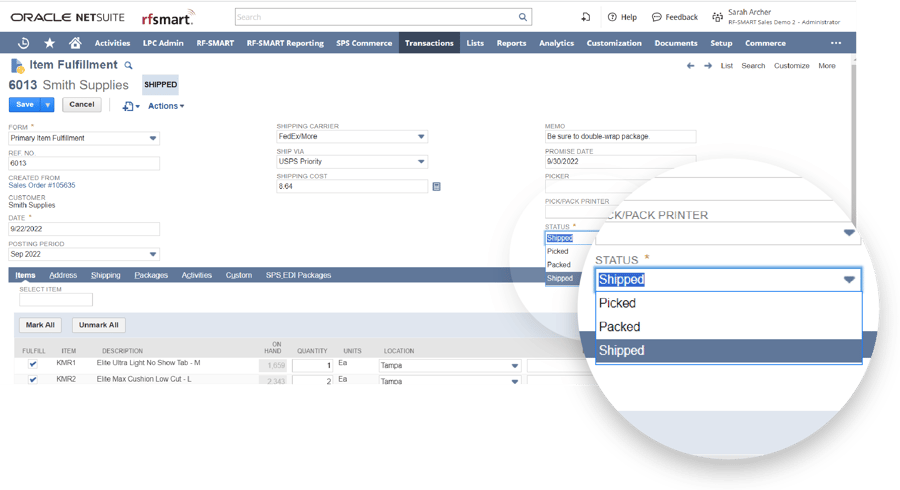

What are picked, packed, and shipped statuses in NetSuite?

The picked, packed, or shipped status in NetSuite is relevant to the Item Fulfillment record status. RF-SMART automatically updates this field as the Item Fulfillment moves through each step of the fulfillment process.

The benefits of leveraging RF-SMART's functionality in your picking process

- Increased Picking Accuracy With RF-SMART's barcode scanning solution, your picking process can be accomplished entirely from the handheld. By scanning to verify the bin and item, your pickers can rest assured that the items they are sending are correct.

- Optimized Picking Routes RF-SMART offers advanced functionality to further optimize picking on the warehouse floor. FIFO, FEFO, Preferred Bin, and Best Bin picking methods will help guide your users in an efficient path.

- Decreased Picking Times As your picking process becomes more streamlined, navigating your warehouse picks will take less time.

ADVANCED PICKING

has the capacity to wave multiple orders together into a single pick path.

The packing step can vary depending on your preferences and the setup of your warehouse.

RF-SMART offers the ability to pack in a variety of ways to fit your processes.

Picking the Right Container for Packing

Most businesses leverage a variety of packaging based on the shipment size and weight. Using RF-SMART's Automation for Mobile Dimensioning can update dimensions of items to NetSuite with the click of a button. Once the dimensions are in NetSuite, RF-SMART Shipping can inform the shipper which carton they should use.

Choosing Shipping Rates

RF-SMART Shipping guides users to the most economical option for shipments based on the customer SLA, ensuring you are getting the best carrier rate for each package.

Reducing Costly Shipping Errors

With our custom rules engine, shippers are guided through the most detailed shipment requirements without any manual intervention. This ensures the most economical shipping carrier/method is being selected.

Accelerating the Shipping Process

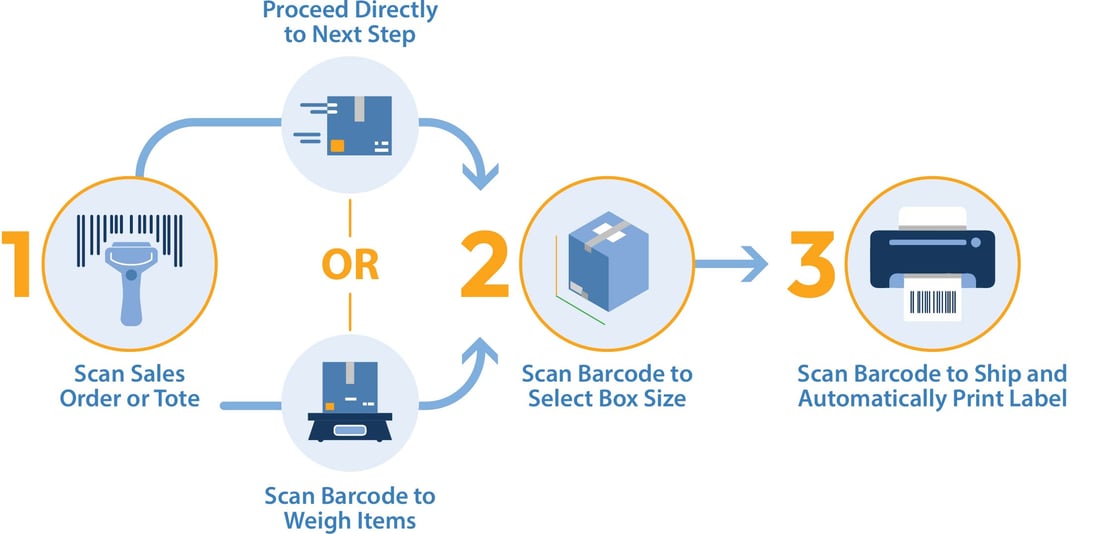

RF-SMART Shipping utilizes the smartest automation to improve overall performance. Customers are seeing massive time savings when shipping packages with our simple “scan, scan, ship” model:

With our Pick/Pack/Ship functionality, complete multiple tasks in processing a sales order in real-time, all from the same workflow:

- The user scans a Sales Order, assigns a box type and then picks the order.

- If additional boxes are required, the user selects a new box and continues picking. There is also an option to move items between boxes prior to updating NetSuite.

- After the picking and packing process is completed, the user is prompted to print shipping labels and packing slips.

- The assignment of box types and the printing of all documents to a user-defined printer can be setup to a default parameter automatically.