For nearly 20 years before their NetSuite implementation, the Synchron team was leveraging a home-grown ERP system, which was entirely on-premise. In late 2019, Tania Grey, Synchron’s Logistics and Planning Manager, wanted to optimize their supply chain process by routing all their data through the cloud. They chose to implement NetSuite and RF-SMART to achieve this goal.

PROACTIVE PROBLEM SOLVING

Like many RF-SMART customers, one of Synchron’s main objectives was to forecast and address supply chain problems before they occur. By using RF-SMART to track their inventory movements, they quickly accomplished the task. “Before RF-SMART and NetSuite, all planning was done via Excel spreadsheets outside of the ERP system, which left room for erroneous planning,” said Tania. “Now, we have a system that is robust and has all the information in one place so we can make decisions quickly and smartly.”

This has allowed Synchron to utilize data in real-time and increase visibility. “You don’t have to wait for downloads during the night to be able to see your stock reports or to see what your sales are like,” said Tania. “With RF-SMART, our data is enabling us to be proactive and not reactive.”

STREAMLINED RECEIVING

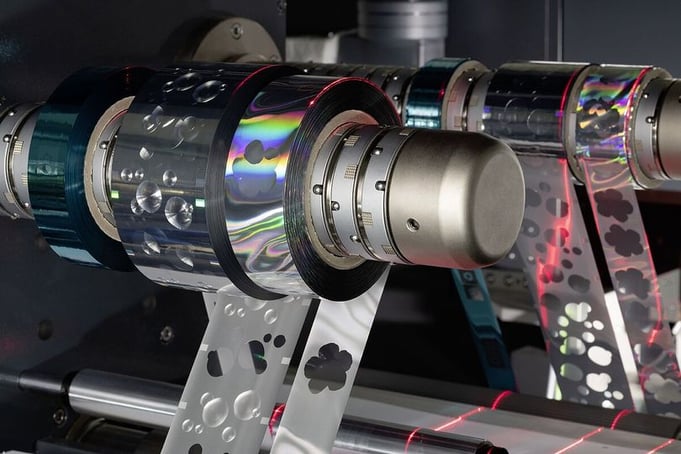

The Synchron team was determined to streamline their receiving process to better navigate international orders from their many suppliers. Each inbound shipment has varying product sizes, most commonly including rolls of foil individually wrapped on pallets. Using RF-SMART's barcode scanning capabilities and NetSuite bins, they were able to configure a process that helped users receive various shipments seamlessly.

All inventory movements are guided by the handheld device and influenced by their data in NetSuite. Their team utilizes RF-SMART’s receiving functionality to scan these items into the warehouse and navigate to the appropriate putaway location. “We do receiving in NetSuite and then we scan items into the bins as staff put them on the shelves,” said Tania. This kept all their data updated in their ERP, providing a clear picture of where inventory is at all times.

PICKING SIMPLIFIED

Another area of optimization for their team was order picking. “Our pickers are mandated to use the scanner from beginning to end,” said Tania. “There’s no manual process in our picking.” This has limited room for error in their processes, further improving their overall pick times and efficiency. This also allowed team members to easily adopt new technology due to the overall ease of use for the end user. Once an order is created in NetSuite, the team uses barcode scanners to pick the product from the appropriate bin and move the picked rolls by pallet or cart to the cutting station.

From there, the Synchron team uses RF-SMART's Transfer Order function to get each roll of product cut down to the appropriate size for specific orders. “Picking is very simple for the user. It starts off with an order, then they commit the stock. The roll then moves via Transfer Order from the bin into what we call a conversion, where the product gets cut,” said Tania. Throughout this entire process, the inventory is being moved and directed from the handhelds, further enforcing accuracy throughout the entire pre-shipping process.

COUNTING ON THE DATA

To further increase their visibility, Tania and her team focused on creating a counting process that was consistent and accurate. “In my 30 years of experience in working stock and inventory management, my aim is always to improve stock counts,” said Tania. Before RF-SMART, the Synchron team was counting on the fly, with sometimes as much as six months between counts. Because of this, true visibility was never accomplished in their inventory. Implementing RF-SMART’s monthly cycle counts was the key to solving this issue. “RF-SMART came onboard and it was like, ‘This is what we want – something that’s quick and easy,’” said Tania.

Not only were they able to improve accuracy, but they also decreased the time it took for team members to review redundancies and missing stock at the end of the month. “Once we were able to accomplish monthly counts, the query list was shorter,” said Tania. “Our team was encouraged to manage the Transfer Orders proactively, and we saw the benefit of monthly stock counts at year end.”

The RF-SMART mobile device-driven counts have also been a more efficient way to accomplish their inventory control. They have decreased the time it takes to do a count by 80 percent with RF-SMART. “I love RF-SMART because you just do your stock count, see your variances, and do your second count. It just narrows it down for me to do the investigation,” said Tania. “I’ve got them to that point where we have up to 100 percent accuracy in our counts, thanks to RF-SMART.”

THE RIGHT SOLUTION

With newly optimized supply chain processes across the board, the Synchron team has been happy with their choice to partner with RF-SMART. “I always felt that if you have a good inventory management system, you’ll always be able to meet your customer’s requirements,” said Tania.

Synchron has been able to rely on the RF-SMART team to navigate supply chain challenges and continue to grow their efficiencies in their warehouses. “The turnaround time for support requests from RF-SMART is brilliant,” said Tania. “If you want a smart, simple, speedy solution, RF-SMART will work for you.”