Navigating the Complexity of Automotive Manufacturing

The automotive manufacturing industry operates within one of the most complex supply chains in the world. With thousands of components, the growing influence of Just-in-Time manufacturing, and pressures to maintain strict product lines, having a strong inventory management system in place is critical to the daily operations of automotive manufacturers.

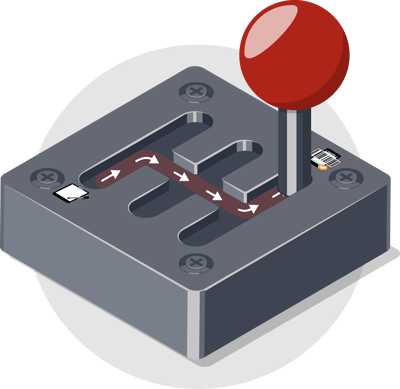

Shift from Manual to High-Performance Inventory Operations

In an industry where production efficiency directly impacts the bottom line, companies in this sector face the constant challenge of balancing inventory levels with production demands. To address this, many automotive manufacturers have adopted Just-in-Time (JIT) manufacturing. While highly effective in managing tight production schedules, JIT requires near-perfect inventory control. If parts or materials arrive too early, capital is tied up in excess inventory, but if they arrive too late, missing components can halt production lines costing hundreds of dollars in lost labor.

Manual processes make keeping this delicate balance nearly impossible. Traditional practices such as handwritten inventory counts, manual stock checks, and paper-based receiving processes introduce significant inefficiencies that not only slow down operations but also increase the risk of errors that can cascade throughout the supply chain, resulting in costly production delays. By automating inventory management, automotive manufacturers can eliminate these inefficiencies and create a more responsive and agile production environment.

Fuel Production Efficiency with RF-SMART & Oracle Cloud SCM

RF-SMART for Oracle Cloud SCM offers a robust inventory management solution that can be tailored to meet the unique needs of the automotive industry. This solution enables real-time visibility and control, allowing manufacturers to maintain optimal stock levels while supporting JIT production requirements.

With RF-SMART, companies in this sector can transform their inventory operations through:

![]()

Real-Time Inventory Visibility

Access accurate, up-to-the-minute information on inventory levels across all locations, enabling better production planning and reducing the risk of stockouts or overstock situations.

![]()

Smart Receiving and Put-Away

Streamline the receiving process with barcode scanning that validates incoming shipments against purchase orders in Oracle Cloud SCM, ensuring the right parts are available for production when needed.

![]()

Efficient Picking and Kitting

Optimize the assembly of component kits for production lines, ensuring all necessary parts are gathered efficiently and accurately before reaching the assembly point.

![]()

Cycle Counting Without Disruption

Maintain inventory accuracy without shutting down operations through systematic cycle counting that can be performed during normal business hours.

![]()

Seamless Integration with Oracle Cloud SCM

Eliminate duplicate data entry and ensure that inventory information is consistent across all Oracle modules, providing a single source of truth for inventory management.

Built for Speed: Precision Labeling and Quality Assurance

The automotive industry deals with many small parts, such as hardware, electronic pieces, and engine components, all needing unique labels for tracking and traceability. Manually creating and printing labels by entering product information can cause errors and slow down operations. To keep production lines running smoothly, companies must automate these processes.

By adopting a system like RF-SMART Print Suite Bridge, automotive manufacturers can benefit from a system that:

• Integrates directly with Oracle SCM Cloud, removing the need for third-party systems• Offers customizable templates that match brand guidelines and specific customer needs

• Prints labels directly from the shop floor with one-touch functionality

• Supports a wide range of printers, including older models

-1.png?width=400&height=400&name=Solution%20(4)-1.png)

Customer Success: Titan International Drives Manufacturing Innovation

"RF-SMART has the flexibility to give us out-of-the-box functionality... We wanted more timely inventory transactions and instant visibility into the movements of our materials – as well as an increase in inventory accuracy. I cannot emphasize enough how easy it is to use."

- Stacy Ripperda, IT Business Analyst at Titan International

Challenges

Titan International, manufacturer of wheels, tires, and assemblies for major customers like Caterpillar, John Deere, and Case New Holland, struggled with significant operational inefficiencies across their 17 locations. Operating with completely manual processes and no automated systems, they lacked real-time inventory visibility and relied on paper-based tracking methods. With 400 users needing to process thousands of manufacturing transactions monthly, these manual methods created bottlenecks and limited their ability to serve major OEM customers effectively.

Solution

To address these challenges, Titan partnered with RF-SMART to implement a comprehensive mobile inventory management solution for Oracle SCM Cloud. The solution includes receiving, picking, sub-inventory transfers, discrete manufacturing, process manufacturing, material transfers, and cycle counting workflows, with specialized manufacturing capabilities to handle their complex wheel and tire assembly operations across multiple facilities.

Results

By implementing RF-SMART for Oracle Cloud SCM, Titan International:

![]() Achieved 99% inventory accuracy with less than 1% variance, eliminating costly discrepancies

Achieved 99% inventory accuracy with less than 1% variance, eliminating costly discrepancies ![]() Improved receiving efficiency by 20% resulting in significant labor cost savings and reduced weekend work

Improved receiving efficiency by 20% resulting in significant labor cost savings and reduced weekend work ![]() Processes 10,000+ manufacturing transactions monthly with real-time visibility into production operations

Processes 10,000+ manufacturing transactions monthly with real-time visibility into production operations![]() Enabled lower inventory levels through accurate tracking, improving working capital management

Enabled lower inventory levels through accurate tracking, improving working capital management

.jpg?width=1200&height=675&name=OC%20Industry%20Titan%20%20(1).jpg)

-2.png?width=200&height=200&name=Solution%20(8)-2.png)

.png?width=200&height=200&name=Results%20(29).png)