CPG Industry Challenges Demand Real-Time Solutions

The Consumer Packaged Goods (CPG) industry is a fast-moving industry that provides frequently replaced items like makeup, household products, clothes, and food and beverages. In this highly competitive market, CPG companies (including manufacturers, distributors, retailers and e-Commerce enterprises) need real-time, accurate inventory data to effectively manage stock levels, ensure slow moving inventory can easily be identified, and accurately track order statuses.

Rapid shifts in demand, driven by seasonality and customer buying behaviors, create constant pressure on consumer goods companies. As they add more SKUs to meet these expectations, many face challenges like longer lead times, limited responsiveness, and frequent stock-outs. These issues are only made worse by paper-based processes that are slow, inefficient, and prone to errors.

Mobile Automation: Your Competitive Advantage

Automating these processes can ensure your team has up-to-date information at all times. By transitioning from paper-driven processes to mobile barcode scanning throughout your operation, you reduce errors and improve the productivity and accuracy of your warehouse team.

|

CPG companies that don't adopt |

• Excessive time identifying and rectifying manual capture errors |

CPG Companies Unlock Warehouse Efficiency with RF-SMART Mobile Technology

Using a mobile Oracle SCM Cloud inventory management system means you can automate manual processes in picking, packing, shipping and inventory counts. With RF-SMART, your staff are prompted to the location to putaway or pick inventory in a fraction of the time without having to rely on tacit knowledge. Even better, these inventory movements are recorded in real-time in Oracle SCM Cloud with every item accounted for in the correct location - saving time, effort, and optimizing your operations.

|

Automation in your warehouse can be applied to: • Purchase Orders, Transfer Orders, Work Orders Receiving and ASN Receiving• Picking and wave picking • Inbound Putaway and Suggested Putaway • Stock Counting (Cycle Count and Physical Inventory) • Material Transfers and Subinventory Transfers • Work Order Execution • Quality Inspection Processes |

Conquering Peak Season Demands with RF-SMART for Oracle SCM Cloud

Consumer packaged goods companies face intense pressure during peak seasons when demand can surge unpredictably. With brand reputation and customer loyalty at stake, CPG businesses need warehouse operations that can scale rapidly while maintaining accuracy and speed.

RF-SMART for Oracle SCM Cloud transforms your fulfillment operations and ensures your orders get processed quickly and accurately through:

![]() Reduced training time for seasonal staff: The intuitive interface helps train seasonal workers in seconds without disrupting operations

Reduced training time for seasonal staff: The intuitive interface helps train seasonal workers in seconds without disrupting operations

![]() Real-time inventory visibility: Complete tracking across inventory and locations helps maintain accurate stock levels during high-volume periods

Real-time inventory visibility: Complete tracking across inventory and locations helps maintain accurate stock levels during high-volume periods

![]() Streamlined workflows: Eliminates manual steps in the fulfillment process, reducing errors and increasing throughput

Streamlined workflows: Eliminates manual steps in the fulfillment process, reducing errors and increasing throughput

![]() Adaptability to changing requirements: The system's configuration capabilities allow CPG companies to adjust workflows as needed during peak seasons

Adaptability to changing requirements: The system's configuration capabilities allow CPG companies to adjust workflows as needed during peak seasons

-1.jpg?width=1200&height=675&name=Color%20Backgrounds%20(16)-1.jpg)

Maximize ROI with Advanced Warehouse Capabilities

To effectively manage your inventory, you will also want to leverage advanced mobile tools to further automate your operations and increase inventory accuracy up to 99.9%:

Advanced Picking Capabilities

RF-SMART supports multiple picking methods including Consolidated Picking, Wave Picking, and Directed Picking with locator sequencing. You can create pick waves directly in Oracle SCM Cloud and send tasks to mobile devices instantly to guide your staff on the most efficient route through the warehouse.

Manufacturing Integration

Your shop floor staff can work quickly and accurately with RF‑SMART's manufacturing capabilities. Work Order Execution helps your team easily report labor and quantities, issue materials, charge resources, and complete operations using an intuitive touch screen interface or scanning straight from the shop floor, all integrated with Oracle SCM Cloud's manufacturing modules.

Leading CPG Winery in Canada: Optimizing Wine Club Operations with

RF-SMART for Oracle Cloud

Challenges

One of Canada's leading wine companies with award-winning brands, faced operational inefficiencies managing complex wine production and distribution across 5 locations. With extensive wine club operations requiring high-volume order fulfillment and seasonal staffing needs, they struggled with manual processes, inconsistent workflows, and the challenge of quickly training temporary workers during peak periods.

Solution

To address these challenges, they partnered with RF-SMART to implement a comprehensive mobile inventory management solution for Oracle SCM Cloud. The solution included receiving, putaway, picking, transfers, cycle counts, physical inventory, ship confirm, manufacturing, and labeling software across their wine production and distribution network, with intuitive workflows designed for rapid user adoption.

Results

By implementing RF-SMART

for Oracle Cloud SCM, they:

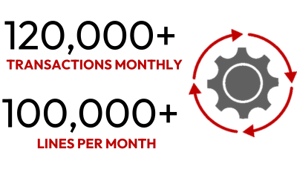

![]() Processes 120,000+ transactions monthly with picking as their primary function at 100,000+ lines per month

Processes 120,000+ transactions monthly with picking as their primary function at 100,000+ lines per month

![]() Achieved exceptional user adoption with new staff picking up the system very quickly, critical for seasonal wine operations

Achieved exceptional user adoption with new staff picking up the system very quickly, critical for seasonal wine operations

![]() Streamlined wine club fulfillment supporting extensive direct-to-consumer operations across Canada

Streamlined wine club fulfillment supporting extensive direct-to-consumer operations across Canada

![]() Improved operational efficiency across all 5 locations with standardized mobile workflows

Improved operational efficiency across all 5 locations with standardized mobile workflows

![]() Enhanced inventory accuracy through automated cycle counting and real-time visibility into wine inventory movements

Enhanced inventory accuracy through automated cycle counting and real-time visibility into wine inventory movements

.png?width=1200&height=675&name=OC%20Industry%20%20(4).png)

-1.png?width=300&height=175&name=Andrew%20Peller%20Limited%20(2)-1.png)

-1.jpeg?width=1200&height=675&name=NS%20Industry%20%20(2)-1.jpeg)